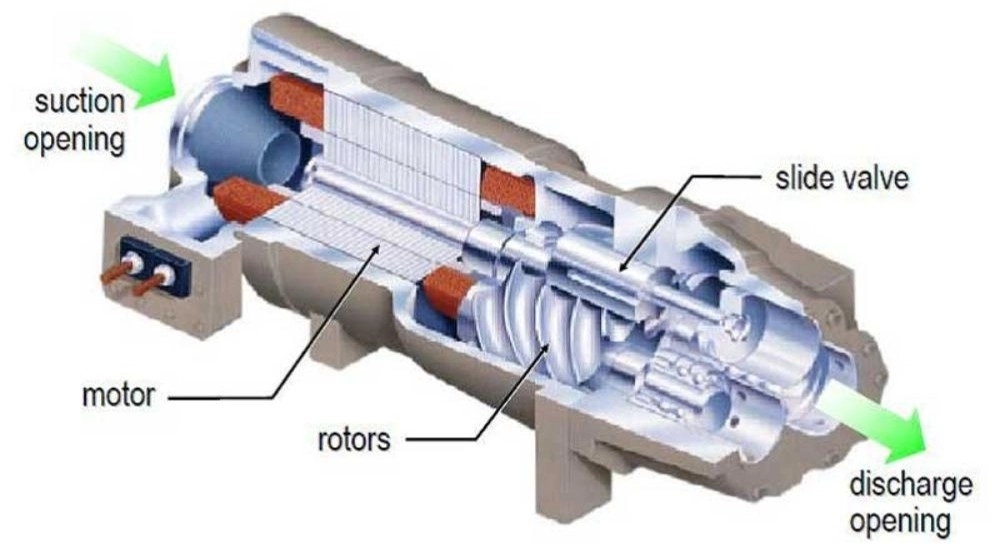

🔲 Rotary screw compressors

One of the common types of positive displacement compressors are rotary screw compressors. These compressors are among the simplest types of air compressors that can be easily maintained; Because they are equipped with an internal cooling system and do not require much maintenance. They are usually large, industrial-sized machines that can be oil-lubricated or oil-free. Rotary screw air compressors generate energy using two internal rotors that rotate in opposite directions. Air is trapped between two opposing rotors and increases the pressure inside the chamber. Due to the internal cooling system, these air compressors are designed for continuous use, and their power ranges from 5 horsepower to 350 horsepower.

The basis of work of rotary screw compressors

1- An opening valve pulls the gas into the compressor chamber. There are two screw rotors in the housing. When the device is on, they spin at high speed. 2- When the propellers rotate, they trap and separate the air in the cavities between the rotors, thereby pulling the air down from the chamber. 3- The size of the chamber decreases and moves away from the opening valve. As volume decreases, pressure increases. 4- Pressure is created and therefore the air is condensed. 5- The air pressure causes the discharge valve of the compressor to open, and this causes the pressurized air to enter the other holding tank. 6- The air is compressed and can be transferred to downstream equipment such as dryers and oil or water separators to dry and remove pollution.

🔲 Reciprocating compressors

Compressed air axial compressors

Axial compressed air compressors are not usually used in construction projects, but are found in high-speed engines of ships or airplanes. They are highly efficient but much more expensive than other types of air compressors and can be up to thousands of horsepower. For this reason, they are mainly dedicated for aerospace research.

The basis of the work of the compressed air axial compressor

The details of the work are very complex; Because the geometry of the blade and the resulting flows are three-dimensional and unstable and can have important viscous and compressibility effects. Each blade on the rotor or stator creates pressure changes similar to the airfoil of a spinning propeller. But unlike a propeller blade, the blades of an axial compressor are close together, which seriously changes the flow around each blade. The blades of the compressor continuously pass the vanes above, which creates unstable changes in the flow. Compressor designers must rely on wind tunnel testing and complex computational models to determine the performance of an axial compressor. Performance is determined by the pressure ratio at the compressor's CPR, the shaft rotation speed required to increase pressure, and an efficiency factor that indicates how much additional work is required over an ideal compressor.

Centrifugal compressors

Centrifugal compressors slow and cool incoming air through a diffuser to increase potential energy. Due to the multi-phase compression process, centrifugal compressed air compressors are able to produce a large amount of energy in a relatively small device. They require less maintenance than rotary screw or reciprocating compressors, and some types can produce oil-free compressed air. They are usually used for more difficult constructions such as chemical plants or steel production centers; Because they can reach a power of about 1000 horsepower.

The basis of centrifugal compressor work

Air is drawn to the center of the rotating propeller by radial vanes and driven towards the center by centrifugal force. This radial movement of air leads to an increase in pressure and the production of kinetic energy. Before the air is directed to the center of the impeller, the kinetic energy also becomes more pressurized by passing through the diffuser and voltage. Each stage includes part of the overall pressure increase of the compressor unit. Depending on the pressure required for the user, a number of steps can be arranged in a series to reach a higher pressure. This type of multi-stage application is often used in the oil and gas industry. Alternatively, in wastewater treatment plants, low pressures and single-stage programs are used to achieve the desired pressure ratio. In modern configurations of centrifugal compressors, very high speed electric motors are used to move the propellers. This allows a compact compressor to work without a gearbox and lubrication system; Therefore, it is oil-free and suitable for applications that require 100% oil-free air.